Creating CBM in ERP

| 4 minutesThere are 2 major types of CBM that are stored in the System:

- Reference CBM;

- Vendor CBM.

In addition to the above 2 types, there are 2 additional types that can only be accessed through a relevant PO/SO:

- Manual;

- Other Order Lines.

This SOP will explain how to handle all the CBM types, where to find them and how to update them.

Due to complexity of CBM information that changes from order to order, the System will have 2 different types of CBM that are stored in different ways and in different places.

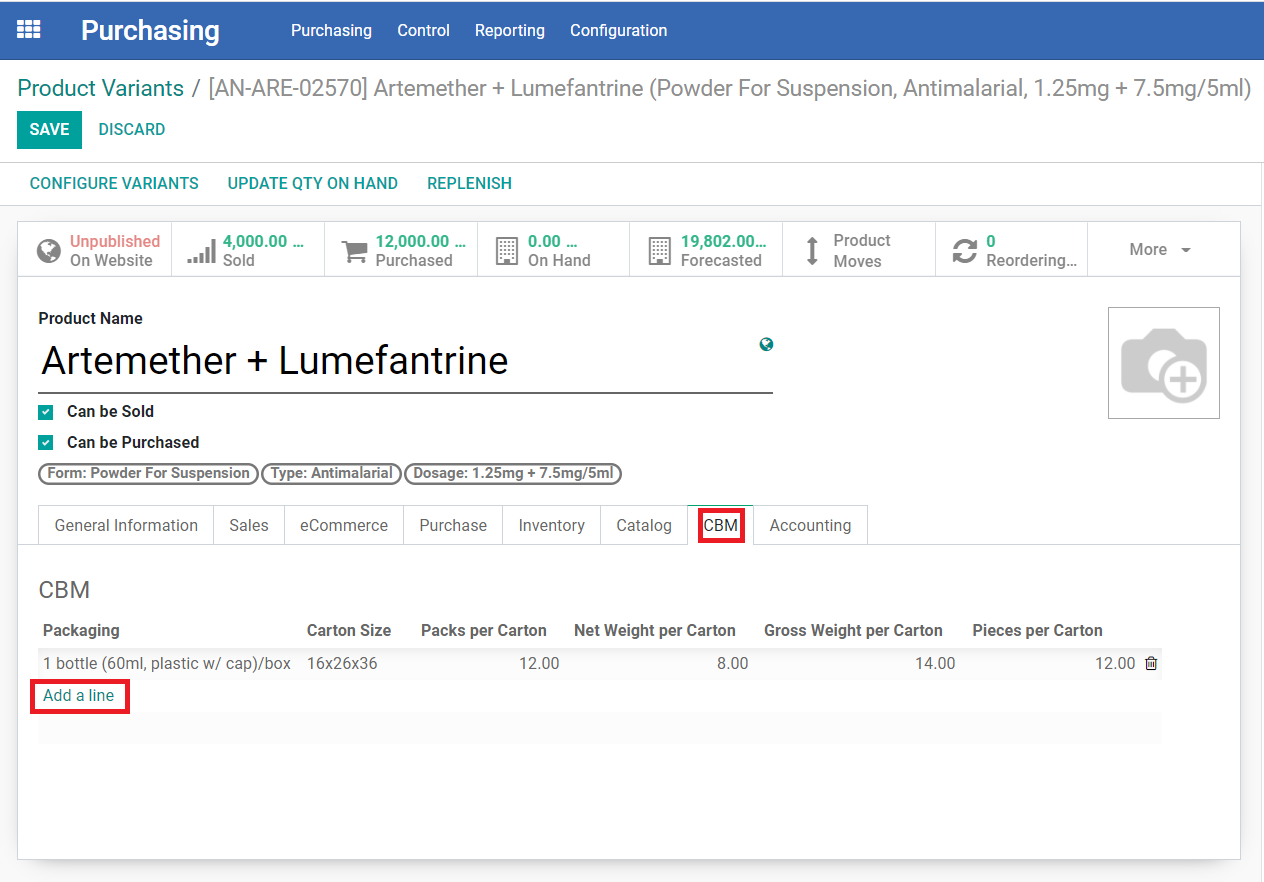

Reference CBM

Reference CBM is the CBM information that is uploaded in the System in reference to a specific Product - Variant - Packaging, but not connected to any Vendor. Reference CBM are stored under each product in ‘CBM’ tab.

Reference CBM are created based on the CBM data of similar products with the same packaging. For example, from the screenshot above, all products with packaging 60ml bottle/box will have similar carton dimensions, the carton can fit similar amount of bottles, so we can assume that all products with packaging 60ml bottle/box will have similar CBM amount and we can use one size for all.

It is important to have Reference CBM to be able to calculate container occupancy and determine freight volume for the products that were never produced by AdvaCare before at early RFQ stages, or when it is urgent to get some CBM idea instead of waiting for the Vendor to provide it. Reference CBM can be used by both Sales Dept. and Purchasing Dept.

Reference CBM can be used in SO and PO.

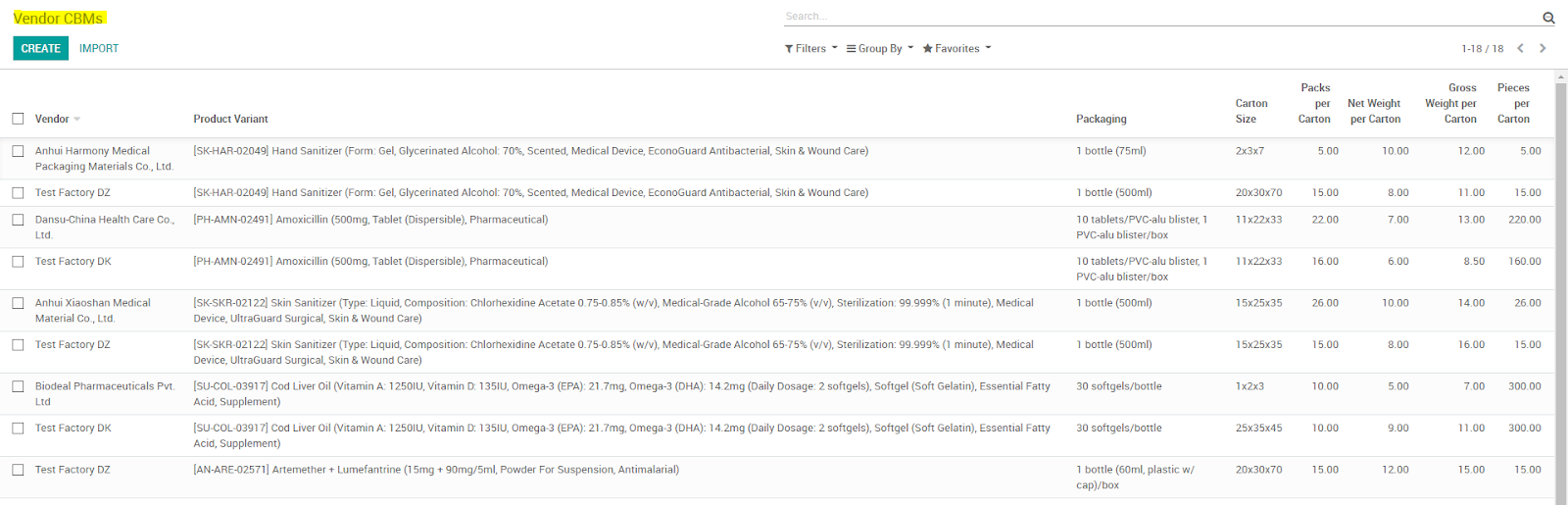

Vendor CBM

Vendor CBM is the CBM information for a specific product produced by a specific Vendor. Vendor CBMs are stored under Vendor CBMs menu in Purchasing Module:

To find the page, go to Purchase Module, in the top menu click on ‘Purchase’ and choose ‘Vendor CBMs’ in the menu dropdown.

Purchasing Dept. and Design Dept. are responsible to update and maintain the data. Each product must have only one CBM record per Vendor per packaging!

Vendor CBMs can be used in SO and PO.

Manual CBM

Manual CBMs refer to CBM information stored for one specific order, and are created manually inside the relevant PO. This option is created to add flexibility to an otherwise very rigid system of storing CBM data.

Manual CBM can also be referred to as Customized CBM. This option will be used only for orders that have a very special kind of packaging that it makes no sense to update Vendor CBM. For example, when the box size had to be changed for a specific Customer - made bigger or smaller. In this case, it is not needed to update Vendor CBM with this information but only record it for the specific PO and SO.

Other Order Line CBM

This type of CBM information is used when we need to refer to Customized CBM in another order. For example, the first order of the Customer had a special kind of the box and therefore, CBM information was stored only locally in the PO and SO of that order. The second order of the same Customer for the same product will need to have the same CBM information as the first order, so it can easily be found through Other Order Line CBM inside new SO and PO.

How to create Vendor CBM

if a new delivery carton value is required, please refer to the document CREATE A DELIVERY PACKAGE.

How to create Reference CBM

if a new delivery carton value is required, please refer to the document CREATE A DELIVERY PACKAGE.