Packaging Designs Mockups-Factory Packaging SOP

| 8 minutesPackaging Process is one of the core processes of any confirmed Order. Packaging design consists of the following elements:

- Primary packaging: blister/pouch/bag/label/tube design/ampoule print

- Secondary packaging: box/bag/label

- Insert (if applicable)

- Tertiary packaging: carton/drum

Process of packaging confirmation is complex and has 3 stages: Mockup packaging, Customer packaging and Factory packaging.

- Mockups. Initial stage where Salesperson works together with Design Dept. to prepare packaging designs. The process on this stage is different for re-ordering products, new products for the Customer, and new products for AdvaCare (Product Development). For re-ordering products, only minor design elements need to be changed (or no elements at all). For a new product for the Customer, some elements might need to be changed according to the requirements of importing country. However, the process stays somewhat simple as long as main content has already been written and approved. Packaging for Product Development is the most complicated process and requires a lot of time and effort from all the departments involved, as it requires a completely new design and content for a product that was never produced by AdvaCare before.

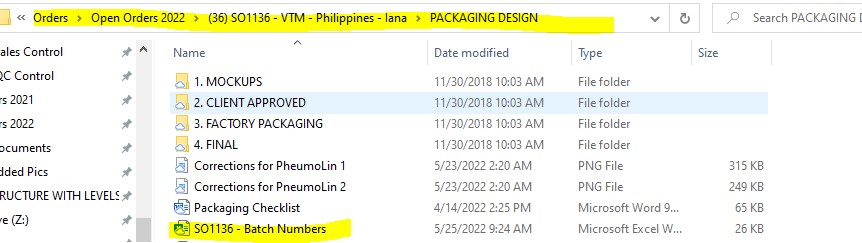

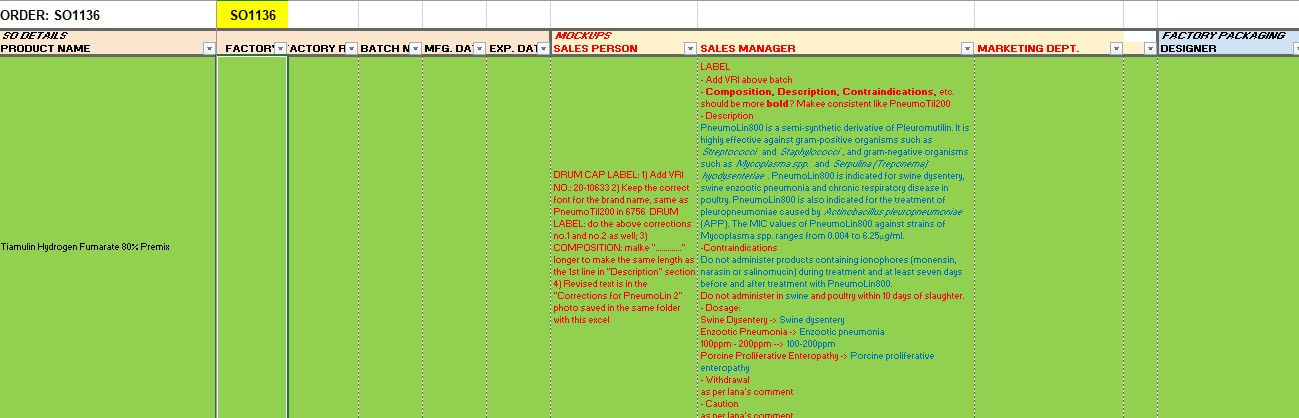

Note: mockups to be checked by Salesperson, assigned BD Specialist (if applicable) and Sales Manager. The comments have to be written in the “XXXX – Batch Numbers” excel sheet in the order folder under the ‘Packaging Design’ folder.

India Orders:

Unlike the orders with China origin, the process differs. There are 2 scenarios: reordered products and newly ordered products. Depending on the scenario, handling mockups for India vendors varies. However, the process of the packaging confirmation with the Customer remains the same with China orders.

- The product has been ordered with the same vendor before:

- 1.1 Mockups sent to vendor ->

- 1.2 Regulatory Dept. of the vendor carefully checks the packaging and requests revision or provides approval ->

- 1.3 Salesperson sends PDCA to the customer and receives it back signed (on this stage, if the customer requires any changes to the packaging, it will go back to the vendor to check by RA again and provide approval until both vendor and customer accept packaging design ->

- 1.4 The packaging gets batch information assigned by the vendor and we receive the mockups including the batch info (which is called “factory packaging”) ->

- 1.5 Salesperson check and makes revisions if any mistakes detected or approves by sending the signed factory packaging to the vendor with Designer and assigned Purchasing Specialist

- The product is being ordered for the 1st time:

- 2.1 Salesperson checks the mockups

- 2.2. The mockups are being sent to the vendor

- 2.3. The RA Dept. of the vendor checks the information on the mockups and provides revisions/approval

- 2.4. Once RA Dept provides full approval, Salesperson sends PDCA to the Customer

- 2.5. After the Customer approves packaging by sending back the signed PDCA, we ask the vendor to get the “factory packaging”

- 2.6. Salesperson checks the factory packaging and revises/approves

- Confirming Packaging with the Customer. Stage where mockups are prepared and packaging needs to be confirmed with the Customer.

- Factory Packaging. Stage where packaging needs to be confirmed with the Vendor. This stage is critical as what is confirmed with the Vendor will be printed for the final product. Factory packaging needs to be checked carefully to avoid any mistakes.

- Vendor provides photos/samples of printed packaging before packing the goods of the order. Stage has to be completed after the factory packaging is confirmed. Salesperson has to request 2 dates from Purchasing Dept.:

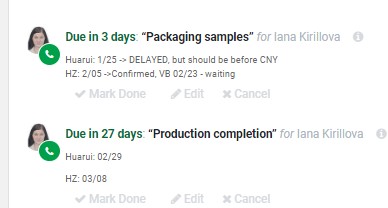

- 1) Estimated date the Vendor will receive the printed packaging for the order

- 2) Estimated date of the production completion

That means that the vendor has already received the product packaging in the past.

It is important to understand the general flow of packaging approval with vendors in India:

In this case, if the product is being reordered, it means that the packaging has already been through the approval process with RA Department of the vendor and unless there is any mandatory revision that we require, there is no need to send the mockups to the vendor again. Note that for the customer it does not change the general process and Salesperson still must check mockups.

If the revision to the reordered product mockup is a must, Salesperson is to send a task to the assigned Purchasing Specialist what revision exactly is needed and for what packaging element, so the vendor only checks on the requested revision.

In this case, according to the general process, the steps remain the same as usual:

* Purchasing is to set a milestone with the estimated dates

The added milestone 'ORD.7 Packaging Samples/Images provided by Vendor’ has to have estimated date and completion date for when the factory sends us the photo (most of the time) or physical sample of the printed for the order packaging of the product, before the product is packed. Sales is to check and make sure the provided Vendor printed packaging is acceptable and inform Purchasing Dept. that the Vendor can proceed with packing. Please make sure to set up yourself activities to get the photos of printed packaging after the factory packaging is confirmed. This way we can eliminate the possible mistakes in printing.

It is important to have packaging free of mistakes, as mistakes will lead to serious problems - for example, the Customer will not accept the final product and ask for the refund; the Customer’s MOH will reject the registration; if there is a mistake on packaging of the registered product, the batch will be recalled which will cause substantial loss. As all products’ designs are AdvaCare unique designs, only AdvaCare will bear responsibility for any issues caused by packaging designs, so it is very important to check it carefully.

Note: This process must be completed in the least amount of time as possible (no more than 7 days!). Salesperson must understand that the production time for the Customer starts when the Customer has confirmed the packaging. This means that the time Salesperson is confirming factory packaging, this is the time of the production days.

See Handling Packaging Designs SOP .

Factory packaging samples (China)/ Shade Cards (India):

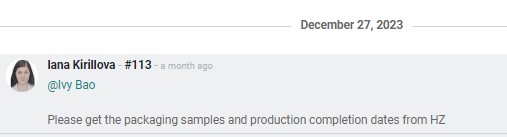

For China orders, once the factory packaging is confirmed, Purchasing can get the estimated date when the packaging samples can be received from the factory. Salesperson needs to send a task to request the estimated dates for the packaging samples and estimated production completion date:

Once received by purchasing, the purchasing specialist will add them to the relevant milestones:

Salesperson will set activities according to the provided dates:

Note: the set date should be the earliest if there are many vendors.

For India orders, there are 2 options:

- New product/New vendor for this product: we will receive shade cards

- Reordered product with the same vendor: we can will receive photos of the packaging samples

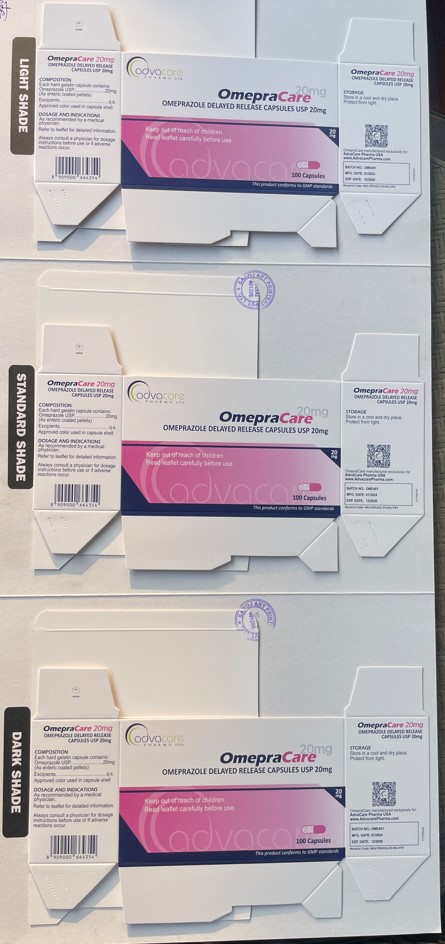

Shade card is a sample from the printing factory with 3 options: Light, Standard, Dark.

They normally are being couriered to AC office in India and Purchasing Specialist will send photos to check the options and select one:

If this is a new product order, choose the most suitable and closest to the colors in mockups.

If this is a reorder of the product but with a new vendor, compare the shade cards side-by-side with the QC samples. They must look as the photo below:

Note: Shade cards will only be provided by vendor if it is the 1st time the vendor produces the product for us.