Handling Packaging Designs (India)

| 11 minutesIndia Vendors have different requirements for packaging designs, therefore the process of handling packaging is different.

India packaging is slower and more confusing, there are many details that need to be taken into account. It is even more important to make sure the mockups are correct the first time they are sent to Vendors, as it will take several weeks to get factory packaging and get it confirmed.

There are several requirements that Purchasing Person needs to follow.

India Packaging Requirements

Example of packaging with Vendor name:

Example of packaging with neutral code:

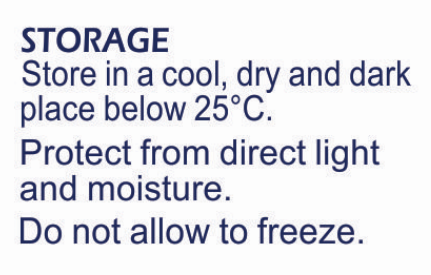

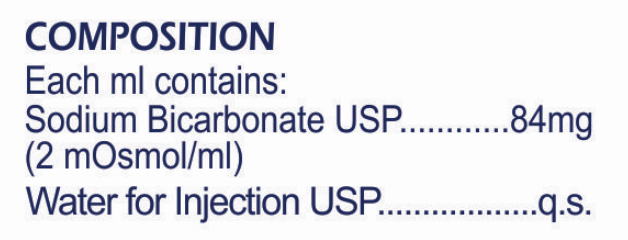

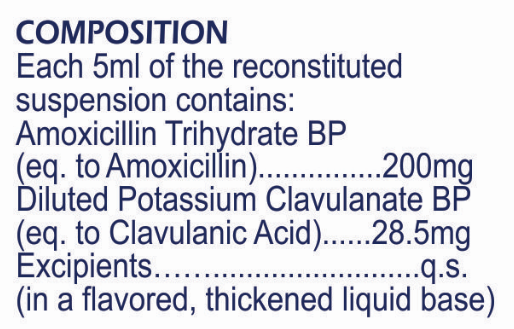

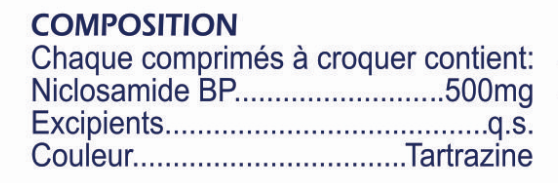

Composition must follow the above format according to the following points:

- “Each 5ml” or “Each coated tablet” or “Each uncoated tablet”, etc.

- “BP/USP” must be in the composition.

- “Excipients…………..q.s” must be present (when applicable).

- For liquid suspensions/syrup, “(in a flavored, thickened liquid base)”.

- For coated tablets, this part should include the color of tablet (not only pink/yellow/etc., but the chemical element that gives color, for example “Titanium Dioxide”.

- For capsules, “(Approved colors used in empty capsule shell)”.

Examples:

Before Starting India Packaging Process

Before starting the process, Purchasing Person needs to understand the following several points that will help to keep the packaging confirmation under control:

- India Vendors work only with CDR files (not AI).

- CDR FILES THAT ARE SENT TO VENDORS ARE LOCKED, which means the Vendor cannot make changes in the text, they can only REPLACE the text - which is not what we want due to format/font/spelling/punctuation etc. related reasons.

- ALL THE CHANGES MUST BE APPLIED ON OUR SIDE due to the previous point. If mockups contain mistakes at the Factory Packaging stage, Salesperson does not need to inform the factory to make changes, changes have to be applied to CDR files and sent to Vendor again with corrections. Some situations can be an exception to this rule, which, however, have to be confirmed with Purchasing Manager.

- If the fonts in Factory Packaging look different from Mockups, it is very likely that CDR files don't render correctly at Vendor’s side. In this case, Design Dept. needs to either change the CDR version to a lower one, or prepare a separate file with the fonts to send to Vendor.

- If the process is followed correctly, Vendor will not need to change anything in the designs. The only thing Vendor needs to do is to save the CDR files as PDF/JPG and send them back. If Mockups have no mistakes and CDR renders correctly on both sides, the Vendor will send back perfect designs that can be confirmed quickly.

- If Purchasing Person notices that Vendor is trying to recreate the CDR files, it means that there are many changes that need to be applied. It is easy to see that files were recreated, as they will look completely different from the Mockups (different colors, fonts, sizes, etc.). Salesperson has to control this process, and inform Purchasing Dept. to get all the changes required in one time, change the Mockups and send the Vendor revised CDR files. If no changes are required, the Vendor will not recreate the files.

India Packaging Checklist

To prepare correct Mockups, Purchasing Person needs to have the following information from the Vendor:

- Sizes of all elements of packaging: box (carton), middle box, blister/label, insert, etc.

- Mockups from previous orders of this Vendor (Salesperson will ask Purchasing Dept. to get mockups of any previous order that Vendor produced before for the same products). Salesperson needs to check the mockups to know the requirements of barcodes/QR codes, size for batch information box, any other requirements for empty space, etc.

- Composition as per PP. If it takes a while to get PP draft, it is enough to make the Composition section according to Mockups received from Vendor as per the previous point.

- Pictures of the finished product of previous orders to see the tablet color and shape, capsule color, bottle type, tray type, etc.

- Manufacturer GMP copy to make sure the Vendor name, address and MFG license number will be the same on the designs. If Vendor name is not required on the packaging, then Salesperson needs to ask Purchasing Dept. to get the neutral code of the Vendor.

- Vendor inserts from previous orders.

- AdvaCare inserts mockups HAVE TO BE PREPARED in CDR according to the insert sizes from the Vendor. Purchasing Person needs to check whether inserts are in CDR format before sending them to the Vendor for the first time. The reason for this rule is that if it is not done, Vendor will have to put the insert text into CDR format themselves. As experience shows, it will mean a lot of mistakes, different formatting, spelling/punctuation mistakes, etc.

- Salesperson needs to request Purchasing Dept. to get shipper dimensions and prepare CBM file in advance, and to be sure whether cartons will be printed or Vendor will apply stickers. If standard box sizes of the Vendor are changed, it will take longer to get the revised carton dimensions.

Salesperson will start working on the Mockups before all of the above information is received. The primary responsibility of the Salesperson is to control the process and not let it take months or go in endless circles. Salesperson can use the best judgement to determine which information is absolutely critical before creating mockups and sending them to Customer, and which information can be received later on. However, all of the above has to be clarified before Mockups are sent to the Vendor for the first time.