Handling Packaging Designs (China)

| 14 minutesThe Packaging Process is one of the core processes of any confirmed Order. Packaging design consists of the following elements:

- Box design;

- Label/blister design;

- Insert;

- Carton design

The process of packaging confirmation is complex and has 3 stages: Mockups packaging, Client packaging and Factory packaging.

It is important to have packaging free of mistakes, as mistakes will lead to serious problems - for example, the Customer will not accept the final product and ask for the refund; the Customer’s MOH will reject the registration; if there is a mistake on packaging of the registered product, the batch will be recalled which will cause substantial loss. As all products’ designs are AdvaCare unique designs, only AdvaCare will bear responsibility for any issues caused by packaging designs, so it is very important to check it carefully.

Note: This process must be completed in the least amount of time as possible (no more than 7 days!). Salesperson must understand that the production time for the Customer starts when the Customer has confirmed the packaging. This means that the time the Salesperson is confirming factory packaging, this is the time of the production days.

MOCKUP PACKAGING DESIGNS

This is the initial stage where Salesperson works together with Design Dept. to prepare packaging designs. The process on this stage is different for re-ordering products, new products for the Customer, and new products for AdvaCare (Product Development).

As this is a critical process, there are several departments involved in this process:

- Salesperson checks all mockups

- BD Specialist (if applicable) is only required to check the mockups under the following situations:

- if it is a new product for existing Customer

- if it is a new Customer that has been handed over by the BD Specialist, whether it is a registered product or no registration product

- Sales Manager checks all mockups

- Sales Director is only required to check the mockups under the following situations:

- if it is a new product for existing Customer

- if it is a new Customer that has been handed over by the BD Specialist, whether it is a registered product or no registration product

Re-Ordering Products

Designer will send a task to the Salesperson when the mockups are prepared for the order.

As the products are re-ordering products, the Salesperson must check several points of reference.

- SO in Odoo

- Last order mockup designs

- Last order QC samples finished product pictures

- CBM file: Carton sizes of mockups must match carton sizes in CBM file (If not, need to check with Designer)

- Compare the product specifications in the mockup designs to the specifications in the SO.

- Product Name, Dosage, Form

- Pack size

- Vendor name if required

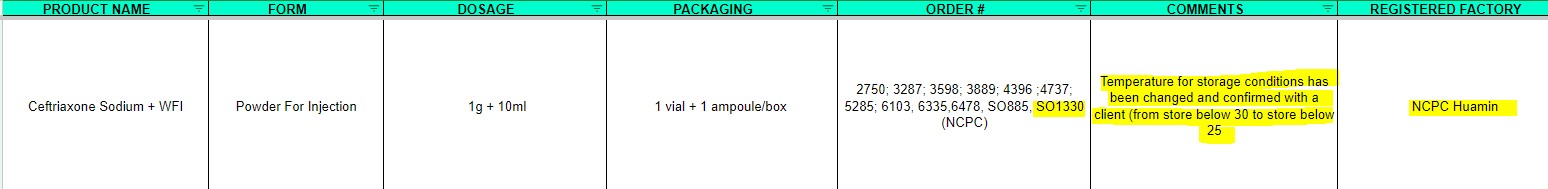

- To find out the last order this product was ordered, check the All Products Ordered excel sheet of the Customer, under the ORDER # column. Also, check the COMMENTS and make sure the packaging design or information is revised according to the comments stated. If a product is registered with a vendor, generally the name of the registered vendor should be included on the packaging. However, there are some Customers that do not require the vendor’s name. Every Customer has specific requirements.

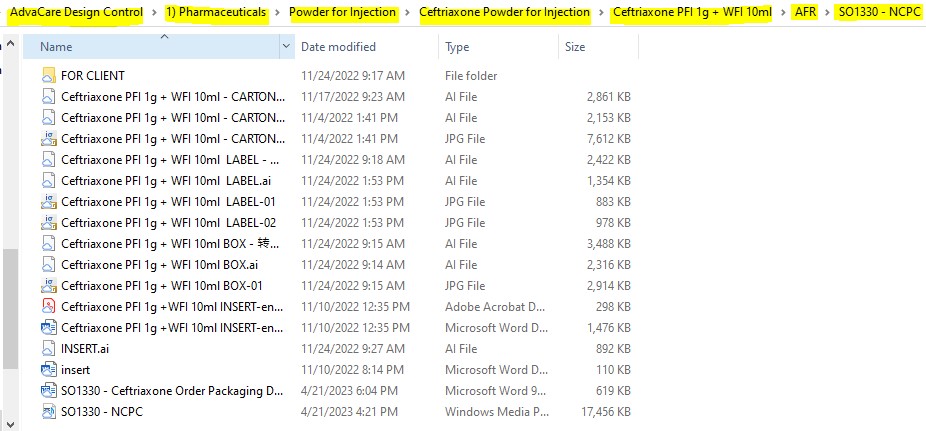

- To check the last order’s packaging design, go to the “Design” folder and follow the path to the correct folder. There you will find the mockups for the last order.

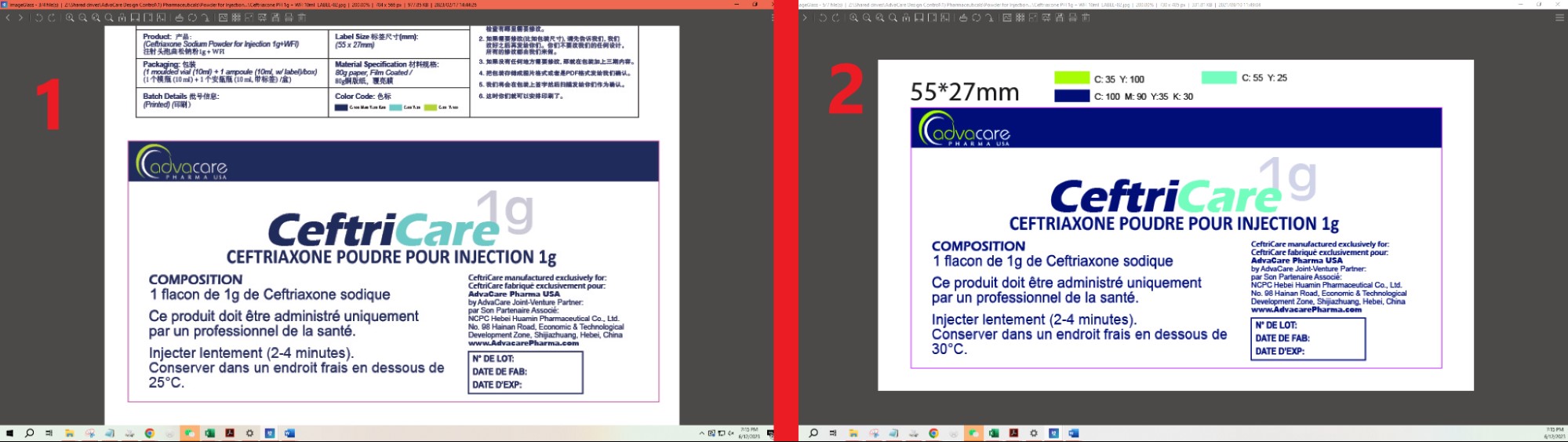

- Compare the designs (box, label, carton and insert) of the last order in one screen and the designs of the current order on the other screen. When comparing designs, the best way to do this is to enlarge both elements to focus on the information. If checking the designs in full image, it is easy to miss the details.

- It is also required to compare the current order mockup design to the finished product pictures of the last order. The reason for this is because sometimes the printed packaging may be different from the packaging confirmed. To check this, go to the QC drive, following the path below to the correct folder.

- If the carton size is different in the mockup from the CBM data, the Salesperson needs to check with the Designer what size is correct. If the CBM file has incorrect measurements, the Salesperson must send a task to the Purchasing Specialist to revise the CBM file.

- If the carton does not have weights on the mockups stage, make sure to check it in the “Factory Packaging” Stage when the mockups are being sent back to us from the vendor. The weight has to match with the CBM file (CBM file must be revised if incorrect and the shipment shall be analyzed on the subject of overweight in case of change of the weights, especially for products in liquid forms).

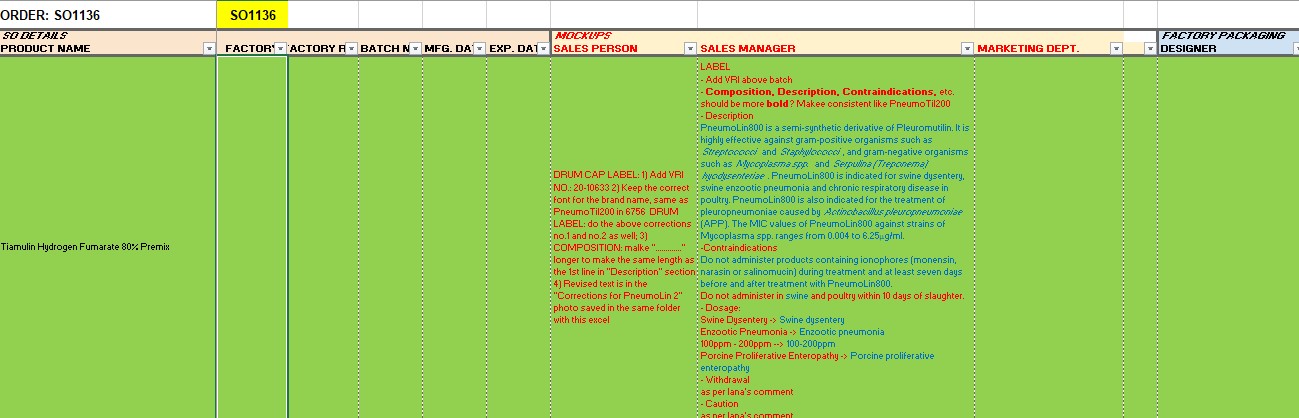

- If there are any mistakes or revisions to be made from the mockups, the comments have to be written in the “XXX - Batch Numbers” excel sheet in the order folder under ‘Packaging Design’ folder:

- Add detailed comments so the Designer will understand what to revise.

- After the Salesperson has added comments, a task should be sent to the Sales Manager to check the mockup designs.

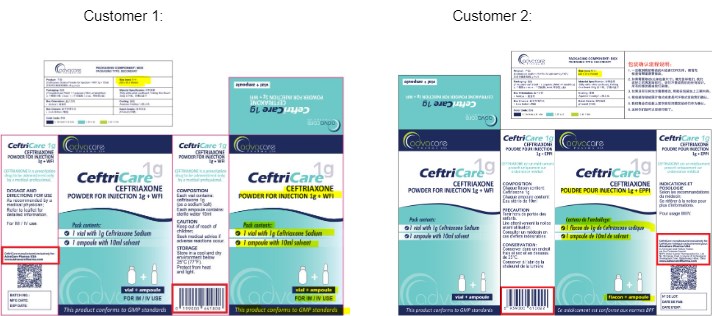

Below is a screenshot of 2 screens: #1 screen has the last order, #2 screen has current order

All of the elements of the design, brand name, logo, content, font sizes, sizes of the packaging forms, colors, formatting and Packaging Components must be checked.

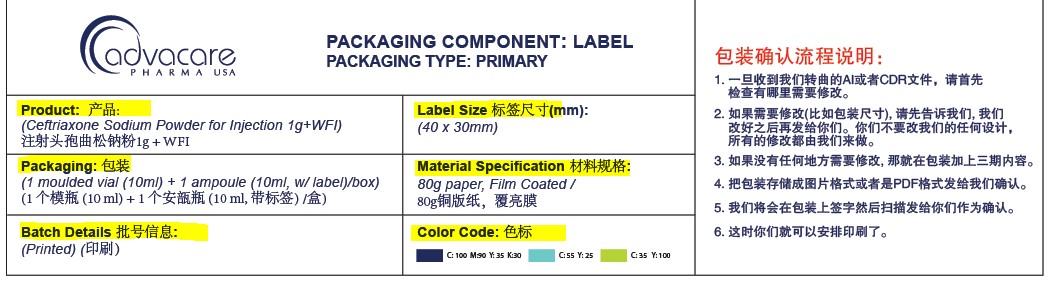

For the Packaging Component, check all information is as per the specifications required:

Check the PACKAGING SPECIFICATION GLOSSARY reference.

Note 1: For Veterinary products specifically, check where the products will be supplied to. Make sure that the mentioned animals are appropriate for the country.

Note 2: If the vendor producing the product is different from the last order, the packaging sizes should be the same as previously ordered. For the Customer, it is important the packaging remains consistent. Therefore, if the sizes or components are different, a task should be sent to Purchasing to inform the vendor of our requirements.

If, for example, the colors printed darker than the design, we may need to adjust the colors on our design. Below is an example of this.

After checking this QC photo, the colors were changed in our mockups to the below. This is why it is also important to check the QC finished product pictures.

Mockups for Cartons always need to be checked with the CBM file provided by Purchasing Department to make sure that the carton size, number of units per carton and the weights (net weight and gross weight) are correct.

Note: if the factory does not include the weight as preprinted with the carton designs information, Salesperson must manually write G.W and N.W. confirmed by the Purchasing Dept. via task and CBM file weight when signing the factory packaging. The packaging CANNOT be confirmed with vendors if the weights are not identified.

Note: mockups for re-ordering products need to be checked only by the Salesperson and Sales Manager.

New Products for the Customer

Designer will send a task to the Salesperson when the mockups are prepared for the order. If there are new products the Customer is ordering, but AdvaCare has produced this product for another Customer, the process is slightly different.

- Check the packaging of other Customers that have ordered this product. The reason to check another Customer’s packaging is just for reference to compare what the designer has prepared for your Customer. But the packaging information must be as per your Customer’s requirements.

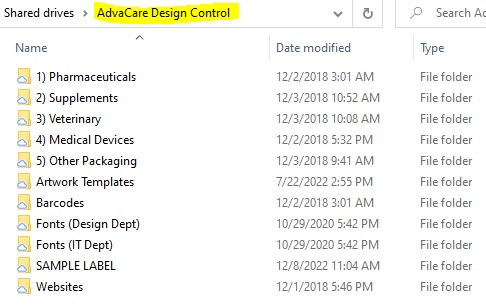

- Prepare the insert according to the insert templates saved here:

- To check the packaging of other Customers that have ordered this product, go to the Design folder and follow the path accordingly. It is best if the product has the same form, dosage and packing as the Customer is ordering.

- Compare the mockup design from the order with other Customer’s design.

- Follow the same process as steps #4-8 in Re-Ordering Products SOP above.

- Salesperson must prepare the insert according to AdvaCare’s format and the Customer’s requirements. The templates for the inserts: Z:\Shared drives\AdvaCare Design Control\Artwork Templates\Insert Templates

For example, the below images are for the same product but there are differences due to each Customer’s requirements: language, barcode # (China starts with 6, US starts with 0), box size. But the color, formatting and placement of the design is consistent.

Note: If the Customer requires the language to be translated into their country’s language, the Salesperson needs to send the final mockups to the Customer as soon as possible since the Customer will need time to translate the content. AdvaCare does not provide the translation.

New Products for AdvaCare (Product Development)

When a Customer is ordering a product that AdvaCare has never produced before, the process requires the involvement of additional departments. The responsibility of the Salesperson is to control the process and make it move forward as soon as possible to avoid delays in production.

See Product Development SOP.

RULES FOR OTHER FORMATS OF MFG DETAILS:

• When using AC HK address, the format should be like this:

AdvaCare Pharma USA

3/F., Jonsim Place

228 Queen’s Road East

Wanchai, Hong Kong

------------------

• When using AC USA address, the format should be like this:

AdvaCare Pharma USA

1623 Central Ave. #210

Cheyenne, WY 82001 USA

------------------

• When adding JV details, should be like this:

AdvaCare Pharma USA

by AdvaCare Joint-Venture Partner:

[Factory name as per the certificates]

[Factory address as per the certificates]

www.AdvacarePharma.com

------------------

• When somehow needs to use AC HK as a division of AC USA:

AdvaCare International Limited

(a division of AdvaCare Pharma USA)

by Advacare Joint-Venture Partner:

[Factory name as per the certificates]

[Factory address as per the certificates]

www.AdvacarePharma.com

CONFIRMING PACKAGING DESIGNS WITH CUSTOMER

After mockup designs have been finalized, Salesperson will send the mockup designs and the PDCA (Packaging Design Confirmation Agreement) to the Customer for confirmation.

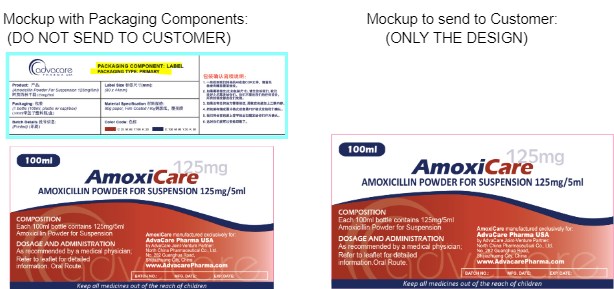

Salesperson will send the mockup design files to the Customer without the Packaging Components. The Packaging Components contain detailed packaging specifications to be shared only with the Vendor. The Customer should not be provided this information to avoid counterfeit products.

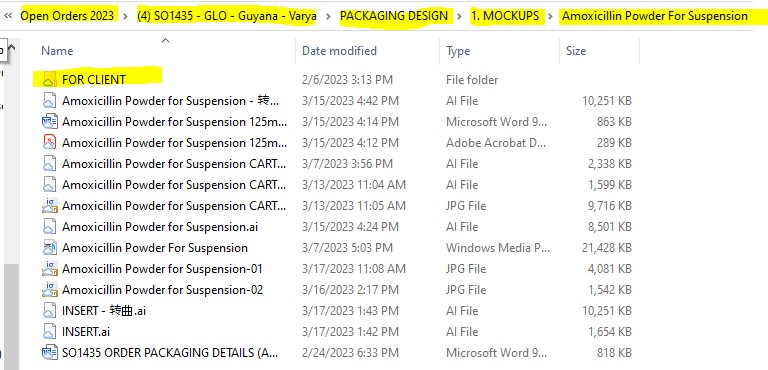

- Designer will prepare design files to send to the Customer without the Packaging Components and save in the ‘FOR CLIENT’ folder under the ‘MOCKUPS’ folder.

- If the Designer has not saved the designs, send a task to the Designer.

- Send the mockup designs and PDCA according to the HANDLING PACKAGING DESIGN CONFIRMATION AGREEMENT SOP" .

Note: Salesperson will only send the jpg files to the Customer. Never send Ai / PS / Word files.

VENDOR PACKAGING DESIGNS

After the Salesperson has received the PDCA signed by the Customer, the next stage is where packaging needs to be confirmed with the Vendor(s). This stage is critical as what is confirmed with the Vendor will be printed for the final product. Factory packaging needs to be checked carefully to avoid any mistakes.

Note: This stage should not take longer than 10 days. For the Customer, the production time starts once the Salesperson has received the signed PDCA. But for AdvaCare, the production time with the Vendor starts only after the Vendor packaging has been confirmed.

- Salesperson will send a task to the Designer informing the Customer has signed the PDCA (Milestone ORD.4) and to send the mockups to the Vendor. At the same time, set up an Activity to the Designer to “get factory packaging” after 3 days. Salesperson will keep extending the Activity until all Vendor packaging has been confirmed.

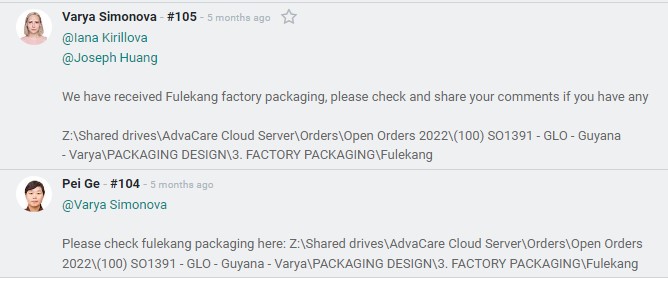

- Designer will send task to Salesperson when Vendor has sent packaging designs back to us. Salesperson must check Vendor packaging immediately and write comments in the excel file. At the same time, Salesperson will send a task to Sales Manager, BD Specialist (if applicable) and Sales Director (if applicable) to check Vendor packaging and write comments in the excel file.

- To check Vendor packaging, open the mockup file in one screen and the Vendor file of the same product on the other screen. Follow the same process as checking the mockups.

- If there are mistakes that originally came from AdvaCare mockups that were not caught before, Salesperson again needs to change the mockups and ask Designer to send the files to the Vendor.

- If there are mistakes that were made by the Vendor and are not present in original mockup files, Designer needs to inform the Vendor.

- Steps 2-5 can be repeated until the Vendor packaging is correct. It is Salesperson's responsibility to understand why each round of revisions happens and avoid the repeat of the situation. While mistakes can happen in mockups, Salesperson cannot let the packaging process take more than 1 extra round of Factory Packaging due to AdvaCare mistakes. Mockups have to be final and absolutely correct before they are sent to Vendors for the first time.

- After related departments confirm Vendor packaging for a product, the Vendor packaging is printed and signed by the Designer, Salesperson, Sales Manager, BD Specialist (if applicable) and Sales Director (if applicable). Design person scans the files and sends the confirmed PDF file to the Vendor.

- When all of the Vendor(s) packaging has been confirmed, Designer will send a task to the Salesperson.

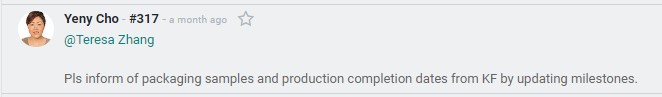

- When the products for a Vendor are confirmed, the Salesperson will send a task to the Purchaser to update the milestones for Packaging Samples date and Production Completion Date.

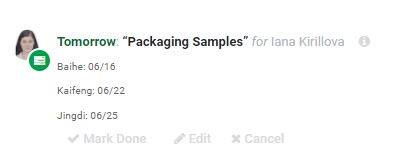

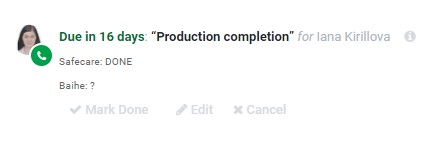

- Salesperson will set 2 activities for themselves for the dates the Vendors will have Packaging samples ready according to the milestones set by Purchaser and for the Production completion dates. This way we can eliminate the possible mistakes in printing before the production is completed.

Note: Vendor packaging will include the Batch No., Manufacturing Date and Expiration Date. This information must be the same on all forms of the packaging.

The added milestone 'ORD.7 Packaging Samples/Images provided by Vendor’ has to have estimated date and completion date for when the factory sends us the photo (most of the time) or physical sample of the printed packaging for the order packaging of the product, before the product is packed. Sales is to check and make sure the provided Vendor printed packaging is acceptable and inform Purchasing Dept. that the Vendor can proceed with packing. Please make sure to set up yourself activities to get the photos of printed packaging after the factory packaging is confirmed. This way we can eliminate the possible mistakes in printing.