Handling CBM

| 5 minutesCBM, or Cubic Meters, is the freight volume of the shipment for domestic and international freight. CBM measurement is calculated by multiplying the width, height and length together of the shipment. For example, if the length, height and width of a cargo is 2.3 meters, 1.4meters and 2 meters respectively, the volume of cargo is 2.3 X 1.4 X 2.00 = 6.44 CBM.

However, usually the data for any shipment of goods is given in cm. Usually CBM is based on carton dimensions in CM and quantity of cartons. Therefore, CM need to be converted to cubic meters by dividing by ‘1,000,000’. So the formula becomes: Length (cm) x Width (cm) x Height (cm) x Quantity of cartons / 1,000,000.

Every RFQ must have CBM excel file saved in the server. CBM excel file has a template with pre-filled formula to calculate CBM of any RFQ. To fill out CBM excel file, Purchasing Person needs to receive the following information from the Vendor:

- Dimensions of the carton (shipper) in cm;

- Quantity of boxes or pieces per carton (shipper).

CBM excel template is saved in each RFQ and ORDER folder. Purchasing Dept. is responsible to prepare the CBM file and provide to Salesperson when the according task has been sent.

It is important to check on CBM information when the potential order is being confirmed in order to arrange for the shipment in the most sufficient way. Normally, customers prefer to have a full container loaded for shipment. Salesperson also needs to keep in mind that some space has to be left for promotional materials that Customer will be receiving altogether with the goods of the order (usually 1-1.5CBM is enough, unless other arrangement have been agreed upon)

The greatest number of shipments are being done by sea. There are 2 types Salesperson has to distinguish: FCL (full container load) and LCL (less than a container load).

The major differences in between FCL and LCL which Salesperson has to pay attention to:

|

|

FCL |

LCL |

|

Cost |

Cost is provided by a shipping line/forwarder for a full container, no matter how much CBM is occupied in the container |

Cost is calculated based on total CBM of the goods |

|

Transportation |

Container has only goods of the Customer and will be unloaded at the port of Destination. |

Container has goods for multiple Customers and will be unloaded at multiple ports according to the vessel’s route (which is why it is risky to include Promotional materials when LCL) |

|

Currency used for Purchase Order in between AdvaCare and ‘Vendor’ |

Does not matter; It can be USD and RMB in one order |

The PO has to be confirmed with RMB as a currency for payment. |

|

Occupancy |

Depending on the container type (GP – standard; RF – refrigerated) each container size will have a limited CBM and weight capacity: |

Does not matter; The cost will be calculated based on the rate/1 CBM |

How to read CBM file in the Server:

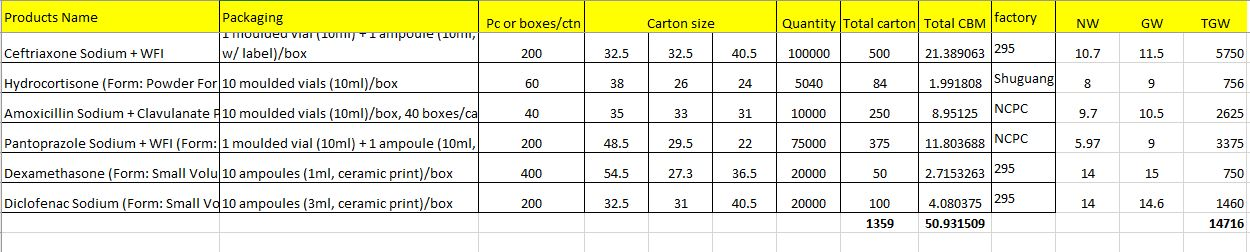

The below is an example for reference what CBM Excel file looks like:

Product Name/Form/Dosage: The information from SO which Purchasing Dept. will take from SO

Packaging: the total number of the product per box/pack

Pc or boxes per CTN: the total number of boxes or packs per 1 carton

Carton size: dimensions of the carton

- CBM Size 1 (cm): length of the carton

- CBM Size 2 (cm): width of the carton

- CBM Size 3 (cm): height of the carton

Quantity: Total number of the ordered product in boxes

Total Carton: Total number of cartons of the product

* This number should always be a full number. Should never be with a decimal (ex: 84.5). If there is a decimal, it means that the last carton will not be full. If a carton is not full, it means there will be empty space in the carton so when loading into the container if there are other cartons on top of the not full carton, the weight will collapse the carton and damage the products in the carton.

Total CBM: Total CBM of the product

Supplier: The chosen Vendor will be shown

NW: Carton’s net weight for the product

GW: Carton’s gross weight for the product

Total Gross Weight: total gross weight of the product

* The gross weight should not exceed 17 tons for 20GP and 25 tons for a 40GP/40HQ

Salesperson need to use the CBM information for the below reasons:

For instance, if the total order CBM is 19CBM, the suggested shipment type will be FCL in a 20GP or 20RF container (depending if the product is temperature sensitive), so the algorithm should be:

20GP container capacity: 28CBM

Space for physical promotional materials: 1CBM

Current total CBM of order: 19CBM

28CBM – 1 CBM – 19CBM = 8CBM of empty space in the 20GP container.

Salesperson has to inform Customer of 8CBM empty space and offer to add other products to the order or increase the ordered products’ quantities to make a full container. It is not a mandatory requirement, however, since Customer pay for a container, it makes sense to use the paid space as well.