Salesperson is responsible for following up on the production completion of the product and once the product has been finished, Purchasing specialist will send a task to inform of the production completion.

Salesperson is to receive the following:

-

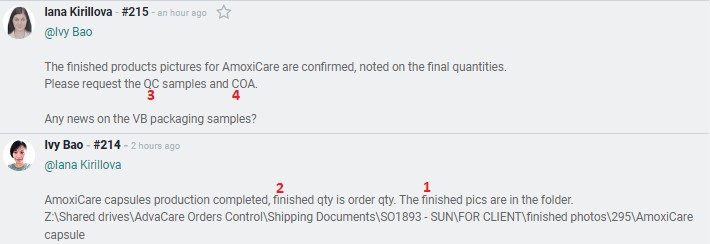

Finished products pictures from the vendor (make sure all packaging elements are saved in the folder, clearly visible) and check with the confirmed factory packaging, CBM file (carton sizes) and OPDs

-

Final products quantities produced (in case of changes, the SO must be revised. Check if the updated quantities make a full carton. If not, make sure the loose carton is packed by the factory the way it is damaged-proof, marked with the number of boxes inside and a photo of the marked carton is provided)

-

Certificate of Analysis (must be received every order even if the Customer does not require it).

Salesperson is to check the information in COAs: batch information, quantity, product characteristics (for example color of the substance), dates mentioned for the tests and report issue date. In case any mistakes are found, we need to question if the product was actually tested.

-

QC samples (must be received for every product).

When checking QC, if there are any revisions to be made to the mockup designs, the Salesperson is to send a task to the Designer to revise the mockups right away. Possible reasons: color printed is too dark and other elements cannot be seen, font size is too small, spelling errors, formatting errors, wrong info on the packaging, etc.

AdvaCare cannot remit the final payment to the vendor if the above 4 points are not completed.