The Quality Control process is intended to review the quality of the finished product and packaging materials. The QC samples should be consistent with the Order Packaging Details specifications and confirmed factory packaging.

The product and packaging information must be compared to both the Factory packaging designs and the SO (check the product name, dosage, composition, specifications and packaging stated in the SO).

• Check that Batch Number, Mfg. Date, Exp. Date are consistent on all packaging materials (box, labels, pouches, blisters, cartons).

• Font size and color should be readable.

• Quality of packaging materials should preserve the integrity of the product. For example, the box paper should have a degree of resistance when it is bent.

• Colors should not be too dark or too light to where other elements cannot be seen or read.

• Inserts must be checked and compared to the confirmed final factory designs.

Note: It is very important that Salesperson checks the QC samples carefully. If there are any packaging mistakes, it should be fixed before sending the goods to the Customer.

When QC samples arrive at the office, Purchasing will created a QC Receipt and send a task to notify Salesperson. Salesperson must check the QC samples at that time for the products received. Do not wait to receive all of the products.

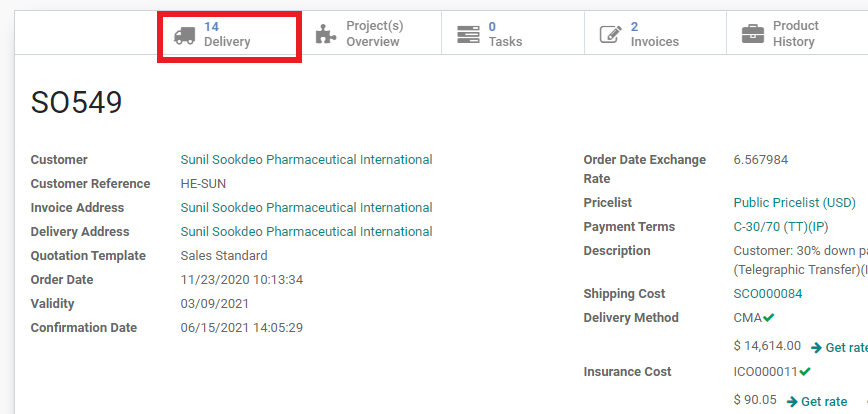

1. Go to the related SO number.

2. Click on “Delivery”:

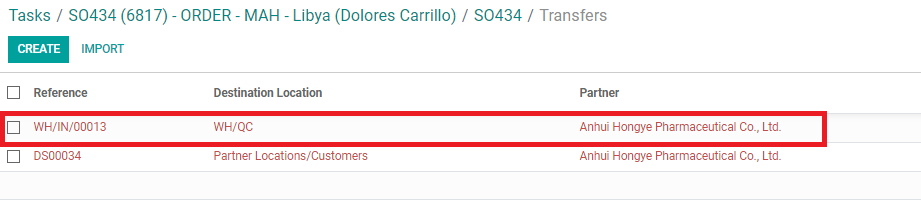

4. Each QC Receipt is per Vendor and will include all of the products produced by this Vendor.

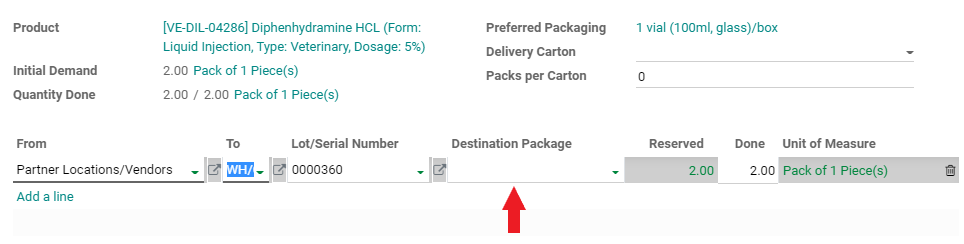

• ‘Initial Demand’: the quantity of QC samples requested to the Vendor by Purchasing Dept.

• ‘Done’: the actual quantity of QC samples received by the Vendor.

5. Click on the [OPERATIONS] tab and click on the [REGISTER] icon of a product line.

7. Go to ‘More Info’ and click on ‘Add a line’. Salesperson is to add the comments after the comments from Purchasing person.

8. Fill the ‘Box Dimensions’ and ‘Factory Info on the Packaging’ sections.

9. Click ‘CONFIRM’

10. Salesperson must send task to Purchasing person and Sales Manager once the incoming QC has been checked. Sales Manager will decide whether we confirm the QC samples or we need to have the Vendor repackage or reproduce. The Vendor will not be paid until the QC has been confirmed by Salesperson.

Note: If there are any discrepancies in the product or packaging from the QC samples, these comments need to be included in the below places:

1) QC in Delivery

2) OPD of the product

3) All Products Ordered excel sheet

11. After sending task to Purchasing person of confirmed QC, Salesperson is to take photos of the QC packaging. These photos are to be very detailed and clear.

Refer to these photos as a reference: ‘Z:\Shared drives\AdvaCare Distributors Cloud Server\VTS - Vetserv - Afghanistan (P; Dolores - C; Geetika)\PACKAGING DESIGN\QC PACKAGING\SO600 (7011)’

12. After Accounting person has sent task that the order is closed, Salesperson must send task to Marketing person to ‘Validate’ the QC. This is part of

the Closing an Order SOP

.